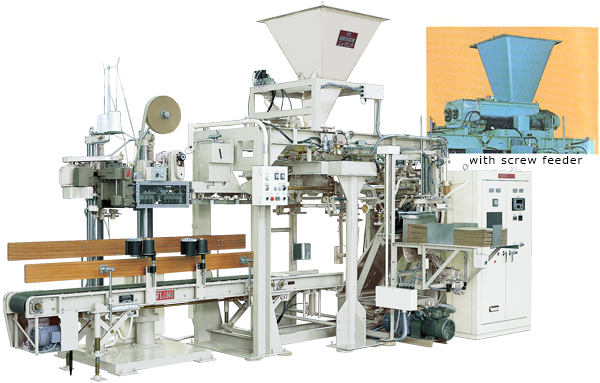

3CM-3G/5G

3CM-3G

Ideal for powdery products. Unlike net weighing, products fill into a bag directly where they are gross weighed, causing neither sticking nor dispersing of the products. Compact and less space required. Compact design saves space and height for installation.

Capacity (bags/hour)

300※

Bag materials

Kraft paper bag, paper cloth bag or PP/PE woven-cloth bag(inner laminated)

Bag size available (mm)

L650~850×W380~500

Filled weight (kg)

20~30

Power required (kW)

Approx.4.3(included for sewing machine)

Air consumption (Nℓ/min.)

400 (0.5MPa)

Machine dimension (m)

Approx. L5.1×W2.5×H3.5

Machine weight (kg)

2,500

3CM-3G-2

Equipped with air ridding device (the first filling & the secondary air ridding by vacuum air inhaler) for accelerating the machine speed of the Model 3CM-3G.

Capacity (bags/hour)

300※

Bag materials

Kraft paper bag, paper cloth bag or PP/PE woven-cloth bag(inner laminated)

Bag size available (mm)

L650~850×W380~500

Filled weight (kg)

20~30

Power required (kW)

Approx.4.5(included for sewing machine)

Air consumption (Nℓ/min.)

600 (0.5MPa)

Machine dimension (m)

Approx. L5.1×W2.5×H3.5

Machine weight (kg)

3,000

OPTIONS

Bag printer

Date/Code printer

Dust extractor

Air ridding device on main conveyor

Bag top former for air ridding

3CM-5G

3CM-5G is designed to place bags at fill-chute directly by swing type feeder, which is different from that of 3CM-3G.

Capacity (bags/hour)

230※

Bag size (mm)

L650~850×W380~500 (for paper bag)

Filled weight (kg)

20~30

Power required (kW)

Approx. 3.2

Air consumption (Nℓ/min.)

Approx. 300 (0.5MPa)

Machine weight (kg)

Approx. 2,500

3CM-5G-2

Equipped with air ridding device (the first filling & the secondary air ridding by vacuum air inhaler) for accelerating the machine speed of the Model 3CM-5G.

Capacity (bags/hour)

230※

Bag size (mm)

L650~850×W380~500 (for paper bag)

Filled weight (kg)

20~30

Power required (kW)

Approx. 3.5

Air consumption (Nℓ/min.)

Approx. 450 (0.5MPa)

Machine weight (kg)

Approx. 3,000

OPTIONS

Bag printer

Date/Code printer

Dust extractor

Air ridding device on main conveyor

Bag top former for air ridding