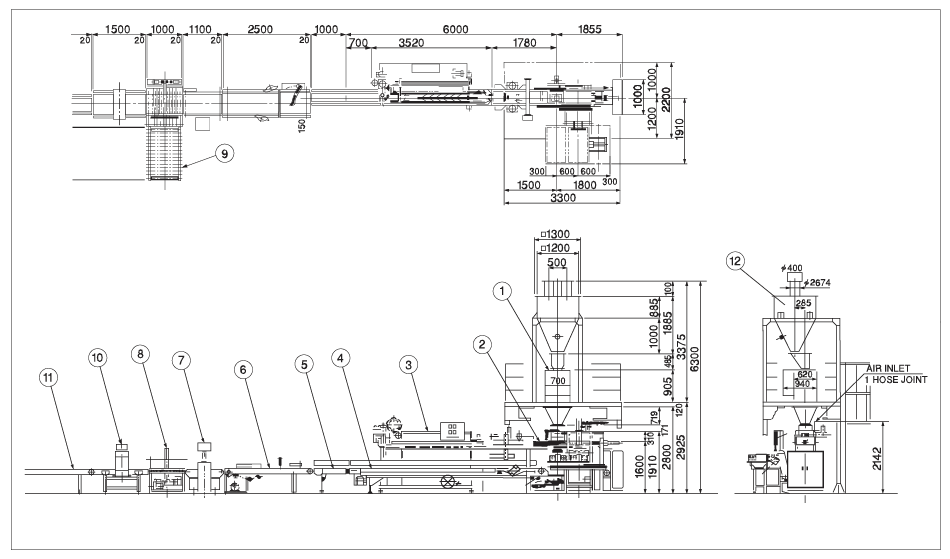

Automatic Bagging System

The total Bagging System from weighing to palletizing

Machine Construction

(1)AUTOMATIC WEIGHING MACHINE

(2)AUTOMATIC BAGGING MACHINE

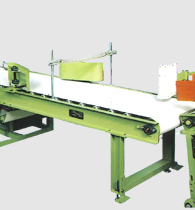

(3)HEAT SEALING MACHINE OR SEWING MACHINE

(4)MAIN CONVEYOR

(5)HEIGHT ADJUST CONVEYOR

(6)BAG REVERSAL CONVEYOR

(7)AUTOMATIC WEIGHT CHECKER

(8)BAG EJECTOR CONVEYOR

(9)FREE ROLLER CONVEYOR

(10)AUTOMATIC METAL DETECTOR

(11)BAG TRANSER CONVEYOR

(12)HOPPER

(A1)INK-JET PRINTER

(A2)BAG PRINTER

(B)BAG INVERSION DEVICE

(C)WEIGHT CHECKER

(D)BAG EJECTING

(E)METAL DETECTOR

(E)METAL DETECTOR

(G)AUTOMATIC WRAPPING MACHINE

NLAP-1

The wrapping machine can wrap bags with film palletized on a table. The table rotates and wrapping film roll moves up to the upper limit and down to the lower limit, then wrapping film wraps spirally bags palletized. The one cycle operation can be done automatically. Inverter-motors control table rotation speed and film roll vertical motion speed.

Film thickness (micron)

20

500

5

Film length (m/roll)

300

Wrapping dimension (mm)

1,600H, 2,125Dia.

Max. weight of the wrapped goods (kg)

2,000

Machine weight (kg)

400

Power required (kW)

1 (3Ph.)

Table size (mm)

1,200×1,200