3CM-P/3CM-PS

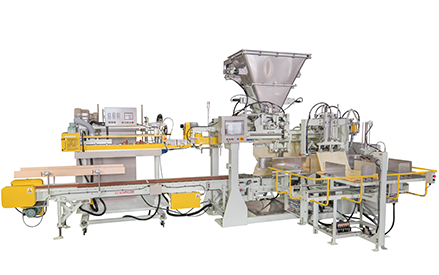

3CM-P

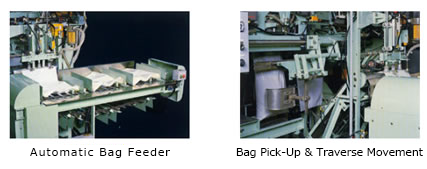

Besides paper bags, woven-cloth and polyethylene bags are widely used in every field of industry, including fertilizer, animal feed and resin pellets and Model 3CM-P is designed to meet a variety of bag materials.

Based upon 3CM-P, a series of models, e.g. 3CM-PVR (with vibration air evacuation), 3CM-PD (double filling system) have been developed for further diversification of bagging requirements.

Capacity (bags/hour)

1200 (depending on products, bag size and bag materials)

Bag Materials

a. Kraft paper bag, paper cloth bag

b. PP/PE woven-cloth bag (inner laminated)

c. Mono-polyethylene bag

Filled Weight (kg)

20-30

Bag Size Available (mm)

L750-950 (in case of a.), L550-1050 (b), L550-750 (c.)

W400-520 × GW75

Air consumption (Nℓ/min. 0.5MPa)

2,000

Power required (kW)

Approx.8 (not included for sewing machine or heat sealer)

Machine Weight (kg)

4,000

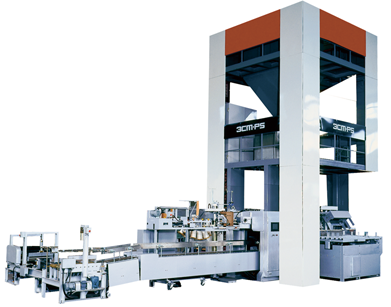

3CM-PS

Hi-speed type of Model 3CM-P equipped with servo-motor drive for traverse movement. Any type of bag closing is available, such as bag stitching, over-tape sealing, heat sealing, and pinch sealing.

Capacity (bags/hour)

1300 (depending on products, bag size and bag materials)

Bag Materials

a. Kraft paper bag, paper cloth bag

b. PP/PE woven-cloth bag (inner laminated)

c. Mono-polyethylene bag

Filled Weight (kg)

20-30

Bag Size Available (mm)

L750-950 (in case of a.), L550-1050 (b), L550-750 (c.)

W400-520 × GW75

Air consumption (Nℓ/min. 0.5MPa)

1,300

Power required (kW)

Approx.12 (not included for sewing machine or heat sealer)

Machine Weight (kg)

4,000

3CM-PSVR Functional Scheme

3CM-P Functional Scheme